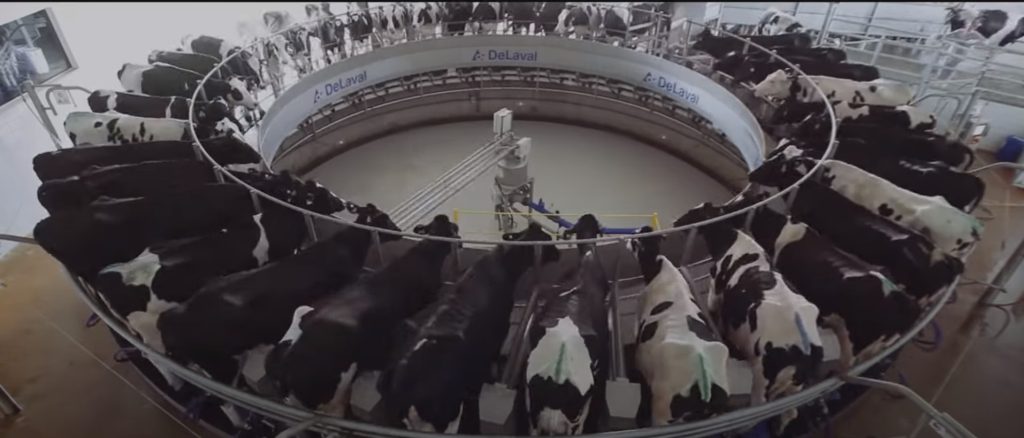

Much is said about efficiency in milk production and, whenever this subject comes up, the type of milking equipment constitutes an important aspect for obtaining it. Despite being one of the oldest milking equipment channels already invented, the Carousel Milking or the equipment known at DeLaval as Roundabout still intrigues some dairy producers and consultants in the area due to its apparent complexity, but, in a few words, we will try to explain its simplicity and main benefits.

The first model of Carousel Milking was launched in 1930 in Europe and, even after design improvements and technological advances, the concept of rotating equipment remains practically intact and helps dairy producers to expand their business throughout the world to this day.

What is a Roundabout or Milking Carousel?

Roundabouts are systems of milking that guarantee a milking routine standardized and effective, allowing you to extract the maximum productive potential of your herd, in less time with less labor. DeLaval has customized rotary platforms that optimize the performance of milking of the herd through constant productivity.

What type of farm does Carousel Milking apply to?

A Carousel Milking is applicable to cattle on pasture, with or without individual feeding in the milking room and for confined cattle (larger or smaller breeds). The number of stalls varies from 24 to 106 animals milked in each complete rotation, always respecting a basic operating sequence.

How does a Carousel Milking work?

A Carousel Milking it works as follows:

- First, the animals reach the rotating platform through the waiting room through an automatic approaching gate (preferably);

- They then enter the platform through individualized access, where they position themselves for the milking process;

- Once on the platform (in rotating motion), the installation procedures begin. milking:

- Screened mug test and pre-dipping (normally in the position of the second bay in relation to the platform entry bay).

- Drying the ceilings and placing the milking set (normally between the positions of bays 7 and 9 in relation to the input bay) – the important thing here is to allow time for the product applied during pre-dipping and time for the milk to let down;

- Monitoring of milking sets and relocation (if there is any early uncoupling). In many cases, this task is shared with those who do the post-dipping;

- Post-dipping that normally starts from the final quarter of the platform rotation. Learn more about DeLaval's 2020 launch, the OceanBlu Barrier.

- Second round (exceptions), if the first was not enough to completely remove the milk.

- Leave the platform and walk towards water, food, rest or some management.

What types of Roundabouts, or Milking Carousels, exist today?

Conceptually, we can divide roundabouts into 3 types:

Carousel Milking – Internal Milking

In the case of internal milking, the milkers position themselves inside the platform.

In general, internal milking roundabouts, also called “Fishbone”, are used in small to medium-sized properties (from 150 to 450 lactating animals), being a system that allows an excellent visualization of all animals. during the milking and requires less manpower in the pit. They are normally family properties, with the milkers being members of the family.

Carousel Milking – External Milking

In the case of external milking, the milkers are positioned outside the platform. External milking, also called “Parallel”, is chosen for large operations, herds of over 450 lactating cows.

Carousel Milking – Robotic milking

There are no milkers, but rather robots carrying out the milking procedures. milking.

“Robotic milking” would apply to the two profiles already mentioned, mainly seeking to reduce labor costs and consistency in milking management.

Why invest in a Carousel Milking?

There are several benefits of investing in a roundabout system, or Carousel Milking, on your farm. Its main benefits are:

Milking yield:

The fact that cows move on a circular platform towards the milkers contributes to a continuous and standardized flow of animals throughout the milking process.

These are equipment that allow the producer to reach milking capacities of more than 600 cows per hour, depending on some other factors, such as: platform size, milker training, animal productivity, animal entry management, milking procedures, etc.

Furthermore, as milkers and cows become accustomed to the milking routine, it is possible to gradually increase the rotation speed of the platform, always respecting the adaptation of both: cows and people.

Animal comfort:

Inside the Roundabout, each cow is positioned individually in its stall, designed specifically for its dimensions, according to its breed (e.g.: Holstein, Jersey or crossbreed).

Even though they are individual, the cows continue to maintain visual contact with their companions, which makes them more calm and comfortable.

Furthermore, there is the possibility of individual feeding in the stall itself and, on most farms, rubber flooring is chosen, which provides great comfort during milking.

Comfort for milkers:

A stationary milker, who focuses on his activity, tends to do it better and with more consistency.

The milking routine in a roundabout allows the milker to walk the least daily, compared to other milking systems (a milker walks about half the distance he would walk in a static “parallel” type equipment). In addition to his well-being, he can focus completely on his task, as he no longer needs to worry about the positioning of the animals, that is, the animals arrive at him already well positioned.

More milk per hour of operation:

A Carousel Milking responds with high capacity as the herd grows. Directly linked to milking yield, the possibility of milking more cows per hour allows the producer to count on an increase in revenue, making his current project viable and/or facilitating his decision-making for future investments.

What factors to consider when investing in a Roundabout?

Roundabouts, or Carousel Milking, they are extremely robust and efficient equipment, however there are several factors that determine the decision to invest in one or another model of milking equipment:

- Quality of labor and its response to increased yield.

- Style of managing this workforce.

- Cost-benefit ratio (milking yield).

- Comfort for milkers (employee retention)

- Animal longevity (due to the comfort obtained in the milking process)

- Animal productivity

- Civil construction for the milking center

- And experience in the activity.

The most important thing for assertiveness in this decision is a clear understanding of the farm's objectives and their relationship with the new investment planned.

Source:

BY DELAVAL