How to reduce dependence on labor in farms.

The difficulty in hiring labor and the increase in operational costs are among the main challenges for rural producers in Brazil. The data confirms this reality: between 2012 and 2024, the agricultural sector lost more than... 2.3 million workersAccording to the IBGE's Continuous National Household Sample Survey (PNAD Contínua), in 2023 alone, there was a reduction of 51,300 employed rural workers.

This scenario directly impacts the daily routines of farms, especially the most strenuous, repetitive, and operational activities—such as manure management. Therefore, the Automation in waste management It ceases to be a trend and becomes a strategic solution to guarantee efficiency, continuity, and control of the process.

The challenge of manual handling on farms.

Traditional waste management relies heavily on personnel, available time, and proper task execution. In a context of increasingly lean teams, this model becomes an operational bottleneck.

In practice, manual handling results in:

-

Constant reliance on experienced operators

-

Results vary depending on who performs the task.

-

Difficulty maintaining a regular routine.

-

Increased risk of operational failures.

-

Accumulation of solids and increased odors when the process does not occur correctly.

When the system fails, the consequences are well known: irregular fertigation, reduced utilization of waste products, and increased environmental risk.

The labor shortage is structural.

According to Embrapa and IBGE, the reduction in the rural workforce is structural and tends to continue. Among the main factors are:

-

Aging of the rural population

-

Migration of young people to urban centers

-

Low attractiveness of operational activities

-

Difficulty in retaining qualified professionals.

Even during periods of new job creation in agribusiness, the lack of available personnel for day-to-day tasks remains one of the main obstacles for farms.

How automation changes the logic of waste management.

Given this scenario, automating waste management means Standardize processes and reduce direct dependence on labor..

With automation, the producer stops acting reactively and starts operating with continuous, predictable, and controlled systems. Thus, management delivers the same results every day, regardless of human availability.

Among the main benefits are:

-

Continuous operation of the system

-

Always homogeneous lagoons

-

Significant reduction in manual interventions.

-

Greater operational control

-

Freeing up the team for higher value-added activities.

AGTO electric stirrer: continuous and reliable stirring

O AGTO electric stirrer It was developed to keep the lagoon consistently homogeneous, without the need for constant manual operation.

In practice, he:

-

Keeps waste in continuous motion.

-

It prevents the formation of crusts and sediments.

-

Ensures consistency in the process.

-

It operates in a programmed and safe manner.

-

It reduces the need for human presence.

With this, handling ceases to be a burdensome task and becomes an automated, reliable, and predictable process.

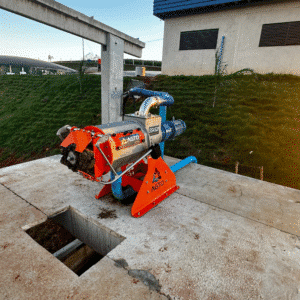

Separator AGTO automated system: fewer steps, more organization.

Another critical step in waste management is the separation of waste. AGTO automatic separator It performs this process continuously, with minimal human intervention.

The system:

-

It automatically separates the solid fraction from the liquid.

-

Reduces the volume stored in the lagoons.

-

It facilitates the reuse of solid waste.

-

Improves the quality of the liquid for application to the soil.

-

It operates autonomously.

In addition to reducing operational effort, the separator brings more organization and predictability to the farm's routine.

Practical results in the day-to-day running of the property.

Producers who adopt automation in waste management observe clear gains:

-

Fewer hours dedicated to handling

-

Reduced dependence on labor.

-

More operational organization

-

Greater system predictability

-

Reducing errors and rework

In a market where labor shortages are chronic, these results are crucial for the continuity of operations.

Automation is also sustainability.

In addition to operational efficiency, automation directly contributes to:

-

Odor reduction

-

Lower risk of overflow.

-

More uniform application of waste.

-

Better environmental control

-

Operation more aligned with legal requirements.

This strengthens the property's image as technologically advanced, responsible, and future-proof.

Why choose AGTO solutions?

AGTO develops equipment designed for the realities of the Brazilian countryside, focusing on:

-

Robustness and durability

-

Operational simplicity

-

Low need for human intervention.

-

Ease of maintenance

-

Specialized technical support

Each project is analyzed individually, ensuring that the automation truly works in the day-to-day operations of the farm.

Conclusion

The data is clear: the shortage of labor in the agricultural sector is a national reality and is likely to intensify. In this context, the Automation in waste management It ceases to be an optional choice and becomes a strategic decision.

With AGTO's electric agitator and automatic separator, producers transform a heavy operation into a more efficient, predictable, and sustainable system, prepared for a scenario of increasingly lean teams.

💬 Speak to the AGTO team. Discover how to automate waste management on your farm.

Request a technical analysis and see how to gain efficiency in your daily life.